Содержание

- Маленький блог скромного айтишника.

- Включаем поддержку протокола SMB1 в Windows 10

- Проверка параметров общего доступа в Windows 10

- Проверяем настройки общего доступа

- Первый случай

- Антивирус или брандмауэр может блокировать сетевые устройства

- Рабочая группа

- Проблема с доступом к общей сетевой папке по SMB1 в Windows 10 (мое решение)

- Как включить SMB1 в Windows 10?

- Вы не можете получить гостевой доступ к общей папке без проверки подлинности

- Вашей системе необходимо использовать SMB2 или более позднюю

Маленький блог скромного айтишника.

Самая популярная проблема при настройке локальной сети – когда компьютер не видит другие компьютеры, общие папки, сетевые накопители и т. д. Эта проблема чаще всего решается настройкой общего доступа и отключением антивируса (брандмауэра), но не всегда. В этой статье я хочу рассказать о нескольких решениях данной проблемы в Windows 10, которые я уже не раз применял на практике. Если у вас компьютер с установленной Windows 10 не видит компьютеры и папки в локальной сети, то первым делом нужно проверить, включена ли поддержка SMB1, так как после одного из обновлений этот протокол отключили. Как бы для безопасности. И это основная причина, по которой на вкладке «Сеть» в проводнике а не появляются сетевые устройства. Как правило, это более старые устройства, которые используют этот самый протокол SMB1, который в десятке отключен.

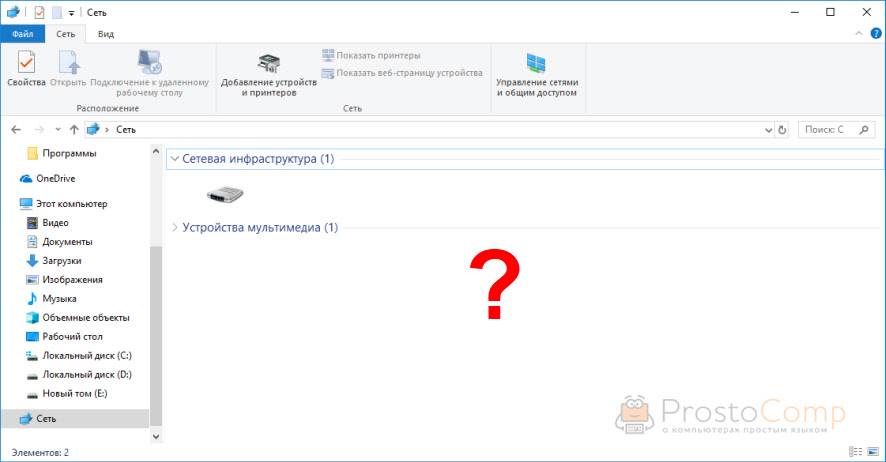

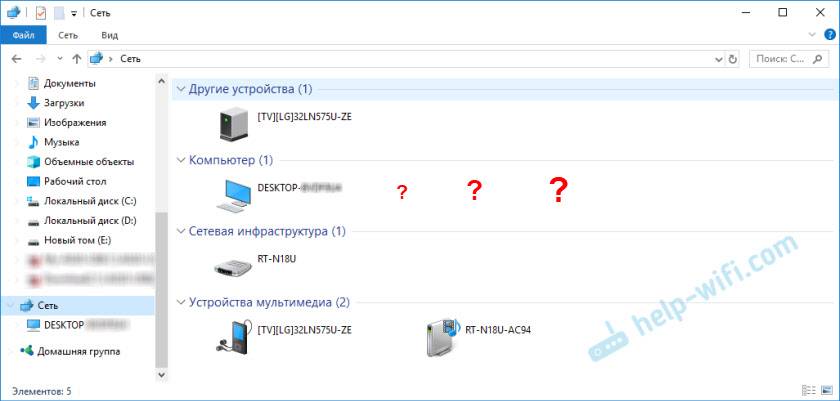

Открываем мы значит вкладку «Сеть» в проводнике Windows 10, где должны отображаться все сетевые устройства. Но видим там в лучшем случае свой Wi-Fi роутер, свой компьютер и может еще какие-то устройства мультимедиа. Другие компьютеры в локальной сети и сетевые папки не отображаются. А с других компьютеров они обычно видны и можно на них зайти. В том числе на этот компьютер с установленной Windows 10.

Как правило, все компьютеры подключены через один маршрутизтор. И многие почему-то думают, что локальная сеть не работает именно из-за настроек маршрутизатора. Но по своему опыту могу сказать, что это не так. Если на маршрутизаторе вы не настраивали какие-то особые функции и ничего не отключали, то все подключенные к нему устройства автоматически находятся в одной локальной сети.

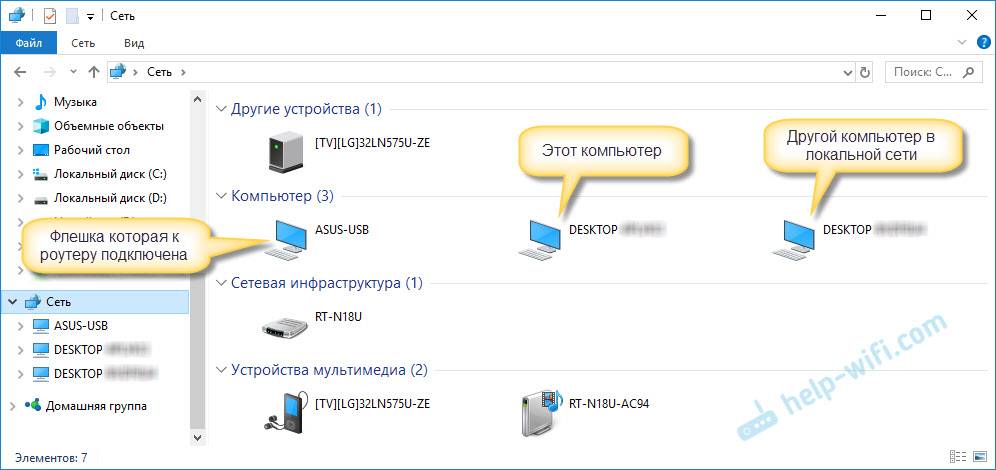

Отдельно хочу рассказать об общем доступе к USB-накопителям через роутер. Если вы подключили к роутеру в USB-порт флешку, или внешний жесткий диск и Windows 10 не видит сетевой накопитель на вкладке «Сеть», то проблема так же может быть в отключенном протоколе SMB1. Так как роутер использует этот протокол для общего доступа к накопителю (сетевой папке).

Включаем поддержку протокола SMB1 в Windows 10

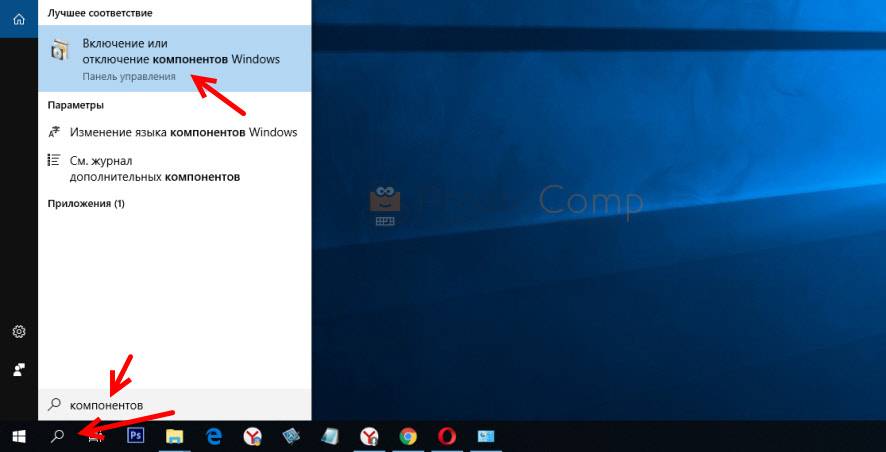

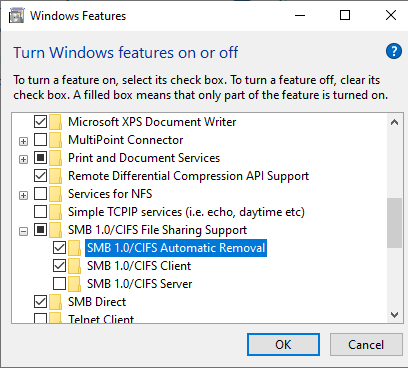

Откройте Пуск (или нажмите на кнопку поиска) и введите «компонентов». Откройте «Включение или отключение компонентов Windows». Или можно открыть это окно через «Панель управления» – «Программы и компоненты» и слева переходим в «Включение или отключение компонентов Windows».

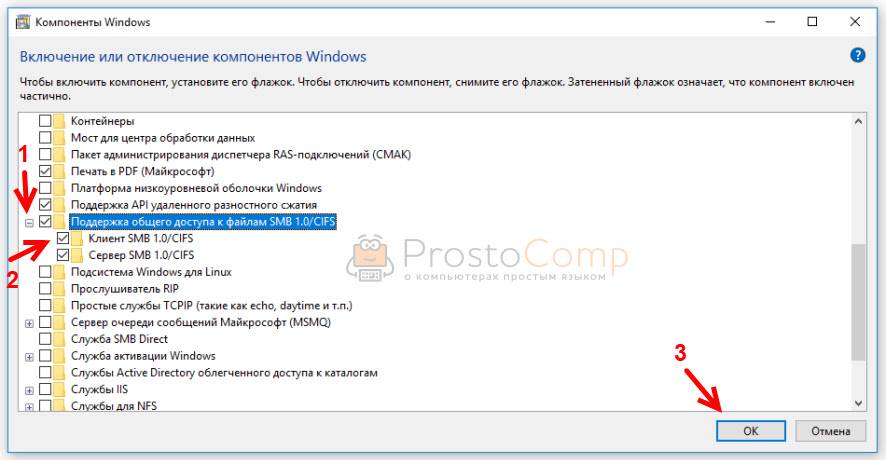

Открываем пункт «Поддержка общего доступа к файлам SMB 1.0/CIFS». Нужно поставить галочку возле «Клиент SMB 1.0/CIFS» и нажать «Ok».

Поддержка старого протокола SMB 1.0 в Windows 10 включена. Теперь система должна видеть все сетевые папки, доступ к которым осуществляется через SMB 1. Можете еще выполнить перезагрузку компьютера.

Проверка параметров общего доступа в Windows 10

Возможно, конечно, на вашем компьютере отключен, или неправильно настроен общий доступ. Из-за чего Windows 10 не может обнаружить другие компьютеры и накопители в локальной сети. Сейчас покажу, как проверить эти настройки.

В Windows 10 (версия 1803) домашняя группа была удалена. Достаточно просто настроить общий доступ к принтерам и файлам.

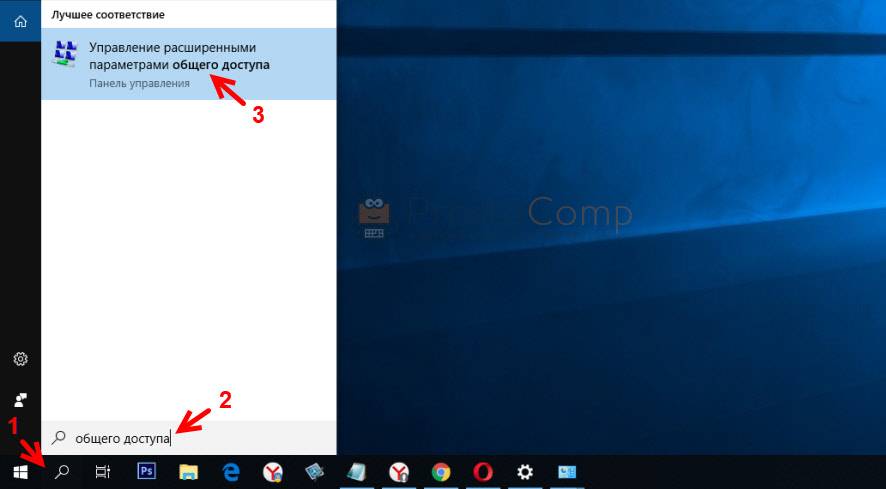

Открываем меню «Пуск» (или нажав на кнопку поиска) и пишем «общего доступа». Открываем «Управление расширенными параметрами общего доступа».

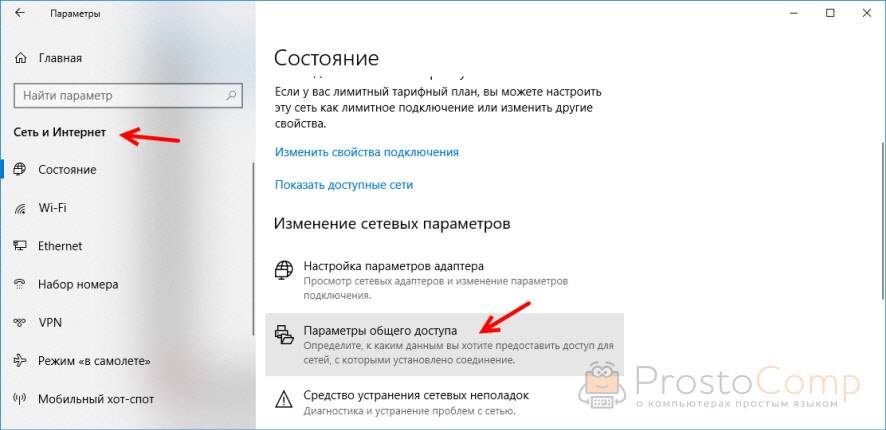

Или можно открыть это окно в параметрах «Сеть и Интернет» – «Параметры общего доступа».

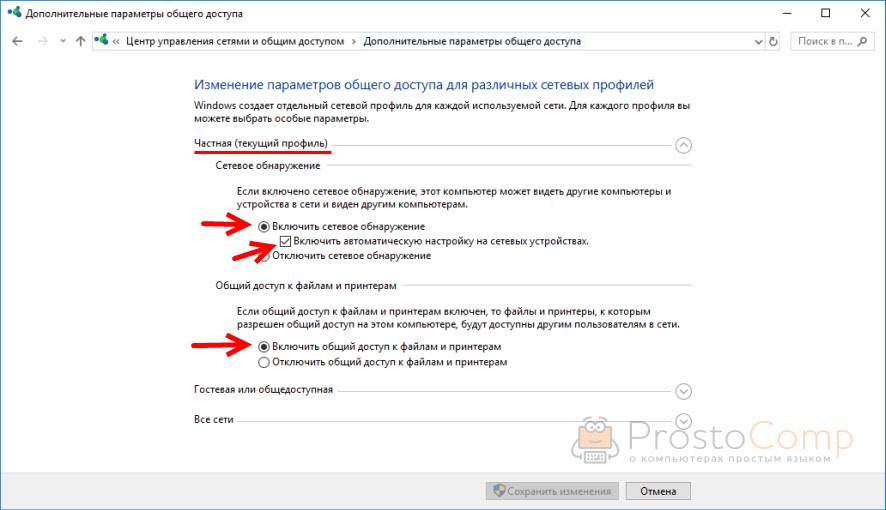

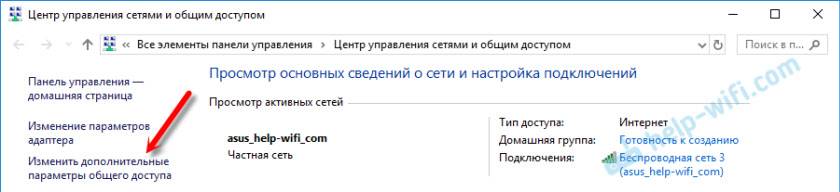

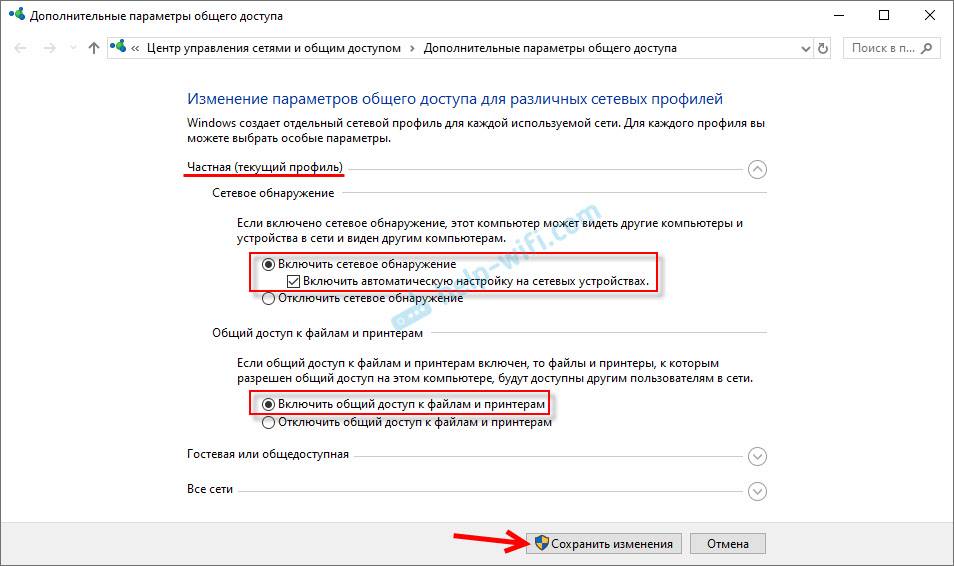

Дальше для текущего профиля (скорее всего это будет частная сеть) установите переключатель возле «Включить сетевое обнаружение» и «Включить общий доступ к файлам и принтерам». А так же поставьте галочку возле «Включить автоматическую настройку на сетевых устройствах».

Нажмите на кнопку «Сохранить изменения».

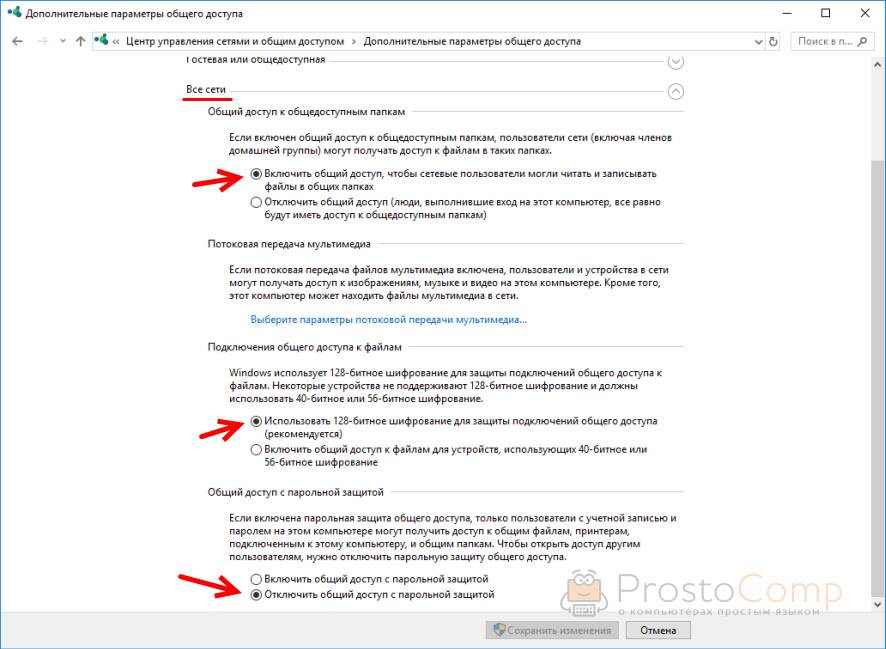

Если это не поможет – попробуйте установить такие настройки для вкладки «Все сети».

Но не рекомендую составлять такие настройки, особенно если вы часто подключаетесь к общественным Wi-Fi сетям.

Еще несколько решений:

- Убедитесь, что ваш компьютер и другие компьютеры с которыми вы хотите настроить локальную сеть подключены через один роутер.

- Отключите антивирус (встроенный в нем брандмауэр) и защитник Windows. Если это не решит проблему – включите обратно.

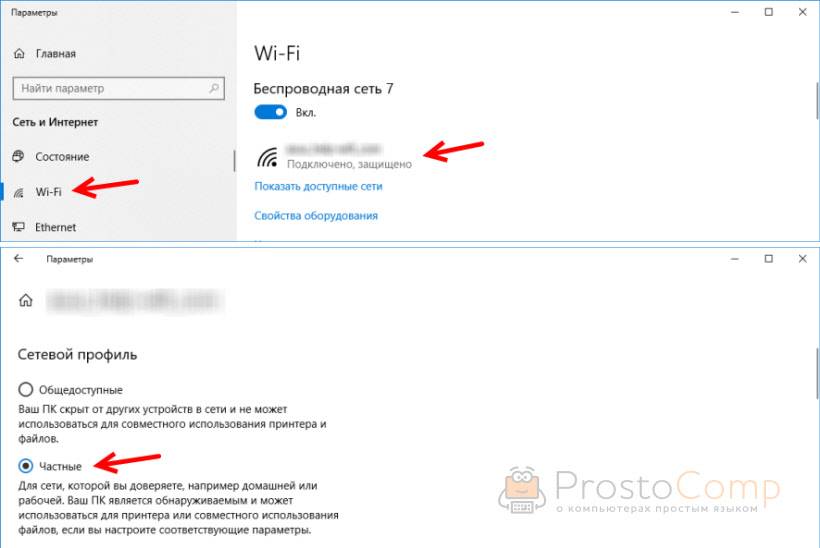

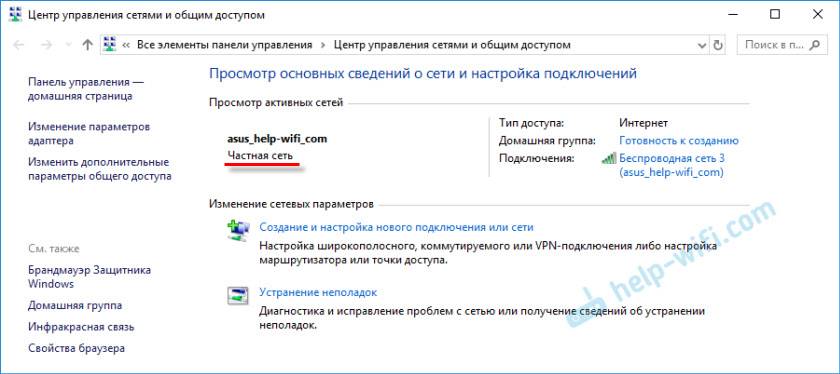

- Если ваш компьютер с Windows 10 (который не видит общие папки и компьютеры в локальной сети) подключен к роутеру по Wi-Fi, то присвойте этой беспроводной сети статус частной (домашней).

- Убедитесь, что на других компьютерах в локальной сети правильно заданы настройки общего доступа. Или на роутере настроен общий доступ к подключенному USB-накопителю.

Буду рад видеть ваши комментарии с другими решениями и вопросами по теме данной статьи!

Привет! Для тех кто не в теме, начну из далека. На компьютерах и ноутбуках с установленной Windows в проводнике есть отдельная вкладка «Сеть». На этой вкладке отображаются устройства из сетевого окружения. То есть, открыв вкладку «Сеть» мы там можем наблюдать компьютеры, сетевые хранилища (NAS), устройства мультимедиа (DLNA), флешки и внешние диски, которые подключены к роутеру и к которым настроен общий доступ. Проще говоря, те устройства, которые подключены через один роутер (находятся в одной сети) и на которых включена функция сетевого обнаружения (устройства, которые могут быть обнаружены в локальной сети) . Там так же может отображаться наш маршрутизатор (раздел «Сетевая инфраструктура») и другие устройства.

Сейчас поясню что и как, и почему я вообще решил написать эту статью. У меня роутер ASUS, к которому я подключил USB флешку, и настроил общий доступ к этой флешке для всех устройств в сети. И что вы думаете, в разделе «Сеть» на всех компьютерах появился этот сетевой накопитель (он там отображается как «Компьютер») , а на моем компьютере он не отображался. То есть, мой компьютер не видел ни флешку подключенную к роутеру, ни другие компьютеры в этой сети. Зато отображался DLNA-сервер запущен на том же роутере. Но это ничего не меняет, так как мне нужен обычный сетевой доступ к накопителю.

Так же я не мог получить доступ к флешке, когда набирал ее адрес //192.168.1.1 в проводнике. Сразу этот адрес открывался через браузере. И мне не удалось подключить этот накопитель как сетевой диск. Его просто не было в списке доступных устройств в сетевом окружении.

Такая проблема, когда Windows 7, Windows 8, или Windows 10 не видит сетевые устройства – не редкость. Это не обязательно должна быть флешка, или внешний HDD, который вы подключили к своему маршрутизатору, как в моем случае. Чаще всего настраивают общий доступ между компьютерами в локальной сети. И точно так же сталкиваются с проблемой, когда компьютеры подключены к одной сети (к одному роутеру) , настройки общего доступа выставлены правильно, а на вкладке «Сеть» пусто. Или отображается только маршрутизатор и ваш компьютер.

Так как причин и соответственно решений может быть много, то я наверное начну с самых простых (которые мне не помогли) и в конце этой статьи поделюсь решением, которое помогло в моем случае. В итоге мой ноутбук все таки увидел все устройства в сети. В том числе сетевой накопитель и другой компьютер, который так же подключен к этой сети.

Но это не значит, что у вас такой же случай. Поэтому, советую проверить все настройки по порядку.

Проверяем настройки общего доступа

Мы будем рассматривать два случая:

- Когда компьютеры не видят друг друга в локальной сети.

- Общий доступ к сетевому накопителю. Это у нас может быть флешка, или жесткий диск который подключен к роутеру, или отдельный накопитель (он же NAS) .

Первый случай

Чтобы компьютеры могли видеть друг друга и отображаться в проводнике в разделе «Сеть», они должны быть подключены через один маршрутизатор. Или соединены напрямую (кабелем, или по Wi-Fi) . Проще говоря, они должны находится в одной локальной сети.

Дальше, на всех компьютерах (не знаю, сколько их там у вас) , желательно присвоить статус сети «Домашняя» (частная). Как это сделать в Windows 10, я писал в статье домашняя (частная) и общественная (общедоступная) сеть Windows 10. В Windows 7 достаточно зайти в «Центр управления сетями и общим доступом» и сменить там статус текущего подключения.

Если после этого по прежнему компьютер не обнаруживает другие компьютеры (или наоборот) , то давайте еще проверим параметры общего доступа.

Для этого, в окне «Центр управления сетями и общим доступом» (если не знаете как открыть его в Windows 10, то смотрите эту статью) нажимаем на пункт «Изменить дополнительные параметры общего доступа».

И для текущего профиля (обычно это «Частная») выставляем параметры как на скриншоте ниже.

Делаем это на всех компьютерах в локальной сети.

Статьи по этой теме:

Не путайте настройки общего доступа с настройками FTP. Настройки FTP-сервера на роутере в данном случае не при чем.

Ну и если другие устройства видят сетевой накопитель и имеют к нему доступ, а на каком-то конкретном компьютере доступа к нему нет, то значит проблема не на стороне роутера. Перебирайте настройки «проблемного» ПК по этой статье.

Антивирус или брандмауэр может блокировать сетевые устройства

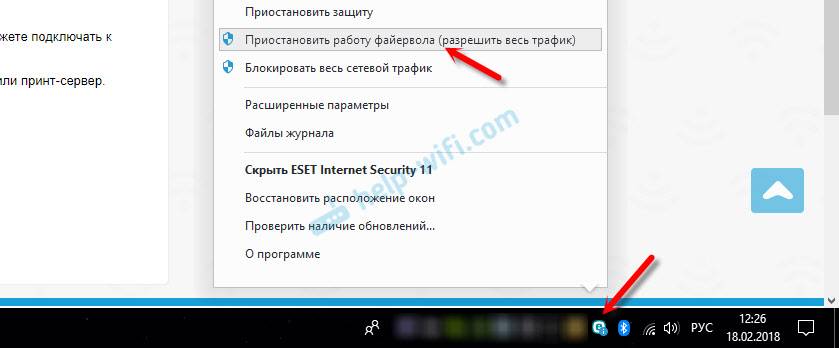

Если вашему антивирусу, или брандмауэру (фаерволу) , который установлен на вашем компьютере что-то не понравилось, то он легко может сделать так, что ни вы не сможете видеть другие устройства в сетевом окружении, ни вас никто не сможет обнаружить.

Правда, у меня после отключения встроенного в антивирусе фаервола проблема не была решена (значит, проблема скорее всего не в нем) , но все ровно мне кажется, что в моем случае без участия антивируса не обошлось.

Поэтому, попробуйте на время полностью остановить работу антивируса, или хотя бы отключить встроенный в него фаервол (межсетевой экран) . В NOD 32 это делается вот так:

Для проверки это нужно сделать на всех компьютерах, которые будут участвовать в локальной сети.

Вполне возможно, что у вас установлены еще какие-то программы, которые могут мониторить сеть и управлять сетевыми соединениями.

Если окажется, что проблема в антивирусе, то нужно добавить свою сеть в исключения. Запретить фаерволу блокировать саму сеть, или сетевые устройства.

Если у вас нет антивируса, то можно поэкспериментировать с отключением/включением брандмауэра встроенного в Windows.

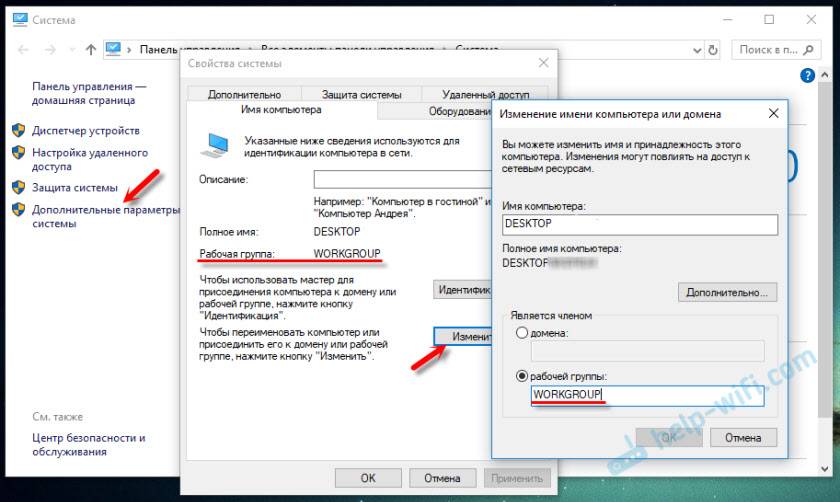

Рабочая группа

Рабочая группа должна быть одинаковой на всех устройствах. Как правило, так и есть. Но желательно проверить. Для этого откройте свойства компьютера «Система» и перейдите в «Дополнительные параметры системы».

Там будет указана «Рабочая группа». Чтобы изменить ее, нужно нажать на кнопку «Изменить».

Еще раз: имя рабочей группы должно быть одинаковым на всех компьютерах.

Если у вас проблема с доступом к сетевому накопителю (к флешке через маршрутизатор) , то в настройках общего доступа на том же роутере ASUS так же указана рабочая группа. Можете посмотреть на скриншоте выше в статье. Она должна быть такой же, как на компьютере.

Проблема с доступом к общей сетевой папке по SMB1 в Windows 10 (мое решение)

Вернемся конкретно к моей проблеме. Все что я описал выше, проверил и перепроверил уже по 10 раз. Пару раз сделал сброс сетевых настроек, но Windows 10 так и не видела другие компьютеры в сети и что самое главное – в проводнике так и не появлялась общая папка в виде флеши подключенной к роутеру. А на других устройствах в сети все определялось без проблем. В том числе мой ноутбук.

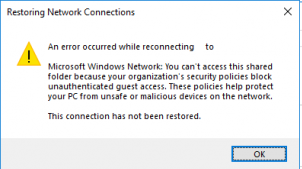

Где-то я прочитал, что можно попробовать открыть общую папку через окно «Выполнить». Нажал сочетание клавиш Win + R, ввел адрес сетевой папки //192.168.1.1 (он же адрес роутера) .

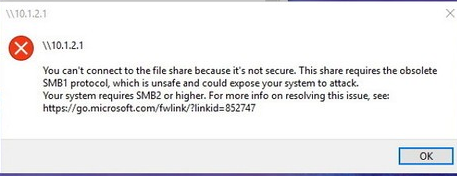

Доступ к накопителю я не получил, но появилась интересная ошибка:

Вы не можете подключиться к общей папке, так как она небезопасна. Эта общая папка работает по устаревшему протоколу SMB1, который небезопасен и может подвергнуть вашу систему риску атаки.

Вашей системе необходимо использовать SMB2 или более позднюю версию.

И ссылка, которую нужно вручную набирать 🙂

Это уже интересно. Хоть что-то.

SMB (Server Message Block) – сетевой протокол, который отвечает за общий доступ к файлам, принтерам и другим сетевым устройствам.

Начал искать. И оказывается, что в Windows 10 отказались от протокола SMB1. Из-за безопасности. А установленный на моем роутере пакет программ Samba походу работает по протоколу SMB1. Поэтому Windows 10 его не видит. Но другие компьютеры, которые так же работают на Windows 10 у меня так же не отображались на вкладке «Сеть».

Так как обновить протокол к SMB2 в настройках роутера я не мог, то решил что нужно как-то включить поддержку SMB1 в Windows 10. И как оказалось, это без проблем можно сделать. В итоге, после подключения компонента «Клиент SMB 1.0/CIFS» у меня все заработало. Система увидела общие папки на компьютерах в сети и сетевую папку настроенную на самом роутере.

Как включить SMB1 в Windows 10?

Через поиск найдите и откройте старую «Панель управления».

Переключитесь на «Мелкие значки» и откройте «Программы и компоненты».

Открываем «Включение или отключение компонентов Windows». Находим пункт «Поддержка общего доступа к файлам SMB 1.0/CIFS». Открываем его и ставим галочку возле «Клиент SMB 1.0/CIFS». Нажимаем Ok.

Если компьютер выдаст запрос на перезагрузку, то перезагрузите его. Если окна с предложением не будет, то выполните перезагрузку вручную.

После перезагрузки, на вкладке «Сеть» – «Компьютер» должны появится все доступные устройства в вашей сети.

Буду рад, если эта статья кому-то пригодится и поможет решить возникшую проблему. Не забудьте написать в комментариях о результатах. Или задать вопрос, куда же без них 🙂

Если вы из Windows 10 не можете открыть сетевые папки на других сетевых устройствах (NAS, Samba сервера Linux) или на компьютерах со старыми версиями Windows (Windows 7/ XP /2003), скорее всего проблема связана с тем, что в вашей новой версии Windows 10 отключена поддержка устаревших и небезопасных версий протокола SMB (используется в Windows для доступа к общим сетевым папкам и файлам). Так, начиная с Windows 10 1709, был отключен протокол SMBv1 и анонимный (гостевой) доступ к сетевым папкам по протоколу SMBv2.

Microsoft планомерно отключает старые и небезопасные версий протокола SMB во всех последний версиях Windows. Начиная с Windows 10 1709 и Windows Server 2019 (как в Datacenter так и в Standard редакциях) в операционной системе по умолчанию отключен протокол SMBv1 (помните атаку шифровальщика WannaCry, которая как раз и реализовалась через дыру в SMBv1).

Конкретные действия, которые нужно предпринять зависят от ошибки, которая появляется в Windows 10 при доступе к общей папке и от настроек удаленного SMB сервера, на котором хранятся общие папки.

Вы не можете получить гостевой доступ к общей папке без проверки подлинности

Начиная с версии Windows 10 1709 (Fall Creators Update) Enterprise и Education пользователи стали жаловаться, что при попытке открыть сетевую папку на соседнем компьютере стала появляться ошибка:

При это на других компьютерах со старыми версиями Windows 8.1/7 или на Windows 10 с билдом до 1709, эти же сетевые каталоги открываются нормально. Эта проблем связана с тем, что в современных версиях Windows 10 (начиная с 1709) по умолчанию запрещен сетевой доступ к сетевым папкам под гостевой учетной записью по протоколу SMBv2 (и ниже). Гостевой (анонимный) доступ подразумевают доступ к сетевой папке без аутентификации. При доступе под гостевым аккаунтом по протоколу SMBv1/v2 не применяются такие методы защиты трафика, как SMB подписывание и шифрование, что делает вашу сессию уязвимой против MiTM (man-in-the-middle) атак.

При попытке открыть сетевую папку под гостем по протоколу SMB2, в журнале клиента SMB (Microsoft-Windows-SMBClient) фиксируется ошибка:

В большинстве случае с этой проблемой можно столкнуться при использовании старых версий NAS (обычно для простоты настройки на них включают гостевой доступ) или при доступе к сетевым папкам на старых версиях Windows 7/2008 R2 или Windows XP /2003 с настроенным анонимным (гостевым) доступом (см. таблицу поддерживаемых версий SMB в разных версиях Windows).

В этом случае Microsoft рекомендует изменить настройки на удаленном компьютере или NAS устройстве, который раздает сетевые папки. Желательно переключить сетевой ресурс в режим SMBv3. А если поддерживается только протокол SMBv2, настроить доступ с аутентификацией. Это самый правильный и безопасный способ исправить проблему.

В зависимости от устройства, на котором хранятся сетевые папки, вы должны отключить на них гостевой доступ.

- NAS устройство – отключите гостевой доступ в настройках вашего NAS устройства (зависит от модели);

- Samba сервер на Linux — если вы раздаете SMB каталог с Linux, в конфигурационном файле smb.conf в секции [global] нужно добавить строку: map to guest = never А в секции с описанием сетевой папки запретить анонимный доступ: guest ok = no

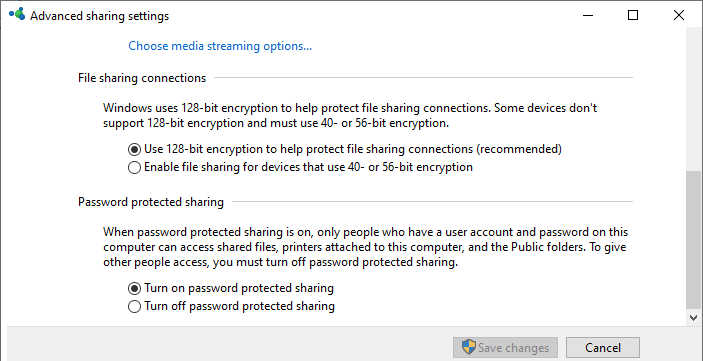

- В Windows вы можете включить общий доступ к сетевым папкам и принтерам с парольной защитой в разделе Control PanelAll Control Panel ItemsNetwork and Sharing CenterAdvanced sharing settings. Для All Networks (Все сети) в секции “Общий доступ с парольной защитой” (Password Protected Sharing) имените значение на “Включить общий доступ с парольной защитой” (Turn on password protected sharing). В этом случае анонимный (гостевой) доступ к папкам будет отключен и вам придется создать локальных пользователей, предоставить им доступ к сетевым папкам и принтерам и использовать эти аккаунты для подключения к общим папкам на этом компьютере.

Есть другой способ – изменить настройки вашего SMB клиента и разрешить доступ с него на сетевые папки под гостевой учетной записью.

Этот способ нужно использовать только как временный (. ), т.к. доступ к папкам без проверки подлинности существенно снижает уровень безопасности ваших данных.

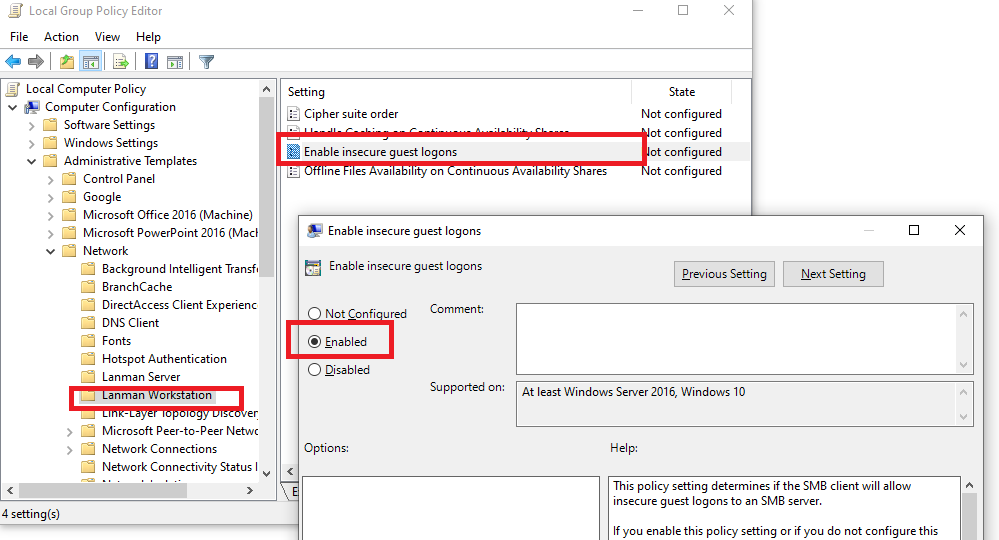

Чтобы разрешить гостевой доступ с вашего компьютера, откройте редактор групповых политик (gpedit.msc) и перейдите в раздел: Конфигурация компьютера -> Административные шаблоны -> Сеть -> Рабочая станция Lanman (Computer Configuration ->Administrative templates -> Network (Сеть) -> Lanman Workstation). Включите политику Enable insecure guest logons (Включить небезопасные гостевые входы).

В Windows 10 Home, в которой нет редактора локальной GPO, вы можете внести аналогичное изменение через редактор реестра вручную:

Или такой командой:

reg add HKLMSYSTEMCurrentControlSetServicesLanmanWorkstationParameters /v AllowInsecureGuestAuth /t reg_dword /d 00000001 /f

Вашей системе необходимо использовать SMB2 или более позднюю

Другая возможная проблема при доступе к сетевой папке из Windows 10 – поддержка на стороне сервера только протокола SMBv1. Т.к. клиент SMBv1 по умолчанию отключен в Windows 10 1709, при попытке открыть шару вы можете получить ошибку:

При этом соседние устройства SMB могут не отображаться в сетевом окружении и при открытии по UNC пути может появляться ошибка 0x80070035.

Т.е. из сообщения об ошибке четко видно, что сетевая папка поддерживает только SMBv1 протокол доступа. В этом случае нужно попытаться перенастроить удаленное SMB устройство для поддержки как минимум SMBv2 (правильный и безопасный путь).

Если сетевые папки раздает Samba на Linux, вы можете указать минимально поддерживаемую версию SMB в файле smb.conf так:

В Windows 7/Windows Server 2008 R2 вы можете отключить SMBv1 и разрешить SMBv2 так: Set-ItemProperty -Path «HKLM:SYSTEMCurrentControlSetServicesLanmanServerParameters» SMB1 -Type DWORD -Value 0 –Force

Set-ItemProperty -Path «HKLM:SYSTEMCurrentControlSetServicesLanmanServerParameters» SMB2 -Type DWORD -Value 1 –Force

В Windows 8.1 отключите SMBv1, разрешите SMBv2 и SMBv3 и проверьте что для вашего сетевого подключения используется частный или доменный профиль:

Disable-WindowsOptionalFeature -Online -FeatureName «SMB1Protocol»Set-SmbServerConfiguration –EnableSMB2Protocol $true

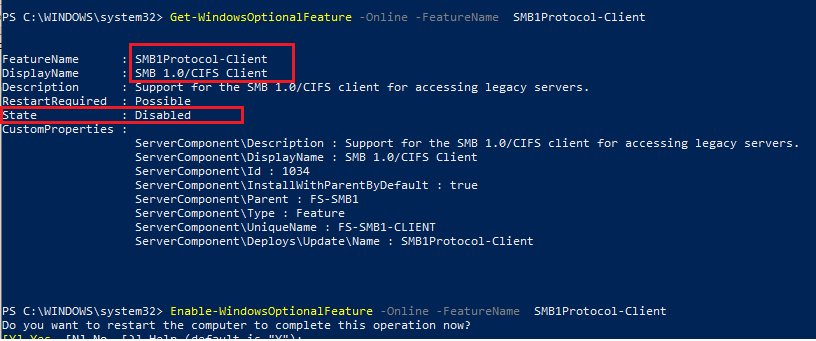

Если ваше сетевое устройство (NAS, Windows XP, Windows Server 2003), поддерживает только протокол SMB1, в Windows 10 вы можете включить отдельный компонент SMB1Protocol-Client. Но это не рекомендуется.

Запустите консоль PowerShell и проверьте, что SMB1Protocol-Client отключен ( State: Disabled ):

Get-WindowsOptionalFeature -Online -FeatureName SMB1Protocol-Client

Включите поддержку протокола SMBv1 (потребуется перезагрузка):

Enable-WindowsOptionalFeature -Online -FeatureName SMB1Protocol-Client

Также вы можете включить/отключить дополнительные компоненты Windows 10 (в том числе SMBv1) из меню optionalfeatures.exe -> SMB 1.0/CIFS File Sharing Support

В Windows 10 1709 и выше клиент SMBv1 автоматически удаляется, если он не использовался более 15 дней (за это отвечает компонент SMB 1.0/CIFS Automatic Removal).

В этом примере я включил только SMBv1 клиент. Не включайте компонент SMB1Protocol-Server, если ваш компьютер не используется устаревшими клиентами в качестве сервера для хранения общих папок.

После установки клиента SMBv1, вы должны без проблем подключиться к сетевой папке или принтеру. Однако, нужно понимать, что использование данного обходного решения не рекомендовано, т.к. подвергает вашу систему опасности.

Источник

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Re: error 027-589 : SMB protocol error 4-049

Hello mscoft,

I don’t know the answer to this one. I would recommend contacting the Support Department for some troubleshooting. The Support options for your device are listed HERE.

Thanks,

CathyO-Xerox

Community Manager

Be sure to click

Kudos for those who have helped you.

Select Accept as Solution for posts that have helped to solve your issue(s)!

- Mark as New

- Bookmark

- Subscribe

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

error 027-589 : SMB protocol error 4-049

Product Name: Xerox D95/D110/D125 Copier/Printer

Operating System: Windows 10

I have two printers in the same network one of them is working the other one is not working. we are unable to use the network scanning. when I access the properties, port setting, to lock for SMB I’m unable to find it. anyone can help

|

WorkCentre 7132 |

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising |

|

out of any inaccuracies or omissions. |

|

|

Service Documentation |

WorkCentre 7132

705P01181 (EDOC/SGS)

Revision

January 2007

***Xerox Private Data***

All service documentation is supplied to Xerox external customers for informational purposes only. Xerox service documentation is intended for use by certified, product-trained service personnel only. Xerox does not warrant or represent that it will notify or provide to such customer any future change to this documentation. Customer performed service of equipment, or modules, components, or parts of such equipment may affect whether Xerox is responsible to fix machine defects under the warranty offered by Xerox with respect to such equipment. You should consult the applicable warranty for its terms regarding customer or third-party provided service.

If the customer services such equipment, modules, components or parts thereof, the customer releases Xerox from any and all liability for the customer actions, and the customer agrees to indemnify, defend and hold Xerox harmless from any third party claims which arise directly or indirectly from such service.

While Xerox has tried to make the documentation accurate, Xerox will have no liability arising out of any inaccuracies or omissions. Changes are periodically made to this document. Changes, technical inaccuracies, and typographical errors will be corrected in subsequent editions.

©Copyright 2007 Xerox Corporation. All rights reserved.

Global Knowledge & Language Services

800 Phillips Road — Bldg. 845-17S

Webster, New York 14580-9791

USA

Printed in the United States of America.

XEROX®, The Document Company®, the stylized X and the identifying product names and numbers herein are trademarks of XEROX CORPORATION.

All non-Xerox brands and product names are trademarks or registered trademarks of their respective companies

WARNING

This equipment generates, uses and can radiate radio frequency energy, and if not installed and used in accordance with the instructions documentation, may cause interference to radio communications. It has been tested and found to comply with the limits for a Class A computing device pursuant to subpart B of part 15 of FCC rules, which are designed to provide reasonable protection against such interference when operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference in which case the user, at his own expense, will be required to correct the interference.

|

Preliminary Working Document |

0/0/00 |

Section Name |

|

No Product Name Assigned |

?-1 |

Introduction

|

About this Manual …………………………………………………………………………………………….. |

iii |

|

Organization…………………………………………………………………………………………………….. |

iii |

|

How to Use this Documentation………………………………………………………………………….. |

iv |

|

Symbology and Nomenclature ……………………………………………………………………………. |

v |

|

Translated Warnings …………………………………………………………………………………………. |

viii |

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

i |

About this Manual

This Service Manual is part of the multinational documentation system for

WorkCentre 7132. The Service Documentation is used in order to diagnose machine malfunctions, adjust components and has information which is used to maintain the product in superior operating condition. It is the controlling publication for a service call. Information on its use is found in the Introduction of the Service Documentation.

This manual contains information that applies to NASG (XC) and ESG (XE) copiers.

Service Manual Revision

The Service Manual will be updated as the machine changes or as problem areas are identified.

Organization

This Service Manual is divided into eight sections. The titles of the sections and a description of the information contained in each section are contained in the following paragraphs:

Section 1: Service Call Procedures

This section contains procedures that determine what actions are to be taken during a service call on the machine and in what sequence they are to be completed. This is the entry level for all service calls.

Section 2: Status Indicator RAPs

This section contains the diagnostic aids for troubleshooting the Fault Code and non-Fault Code related faults (with the exception of image quality problems).

Section 3: Image Quality

This section contains the diagnostic aids for troubleshooting any image quality problems, as well as image quality specifications and image defect samples.

Section 4: Repairs/Adjustments

This section contains all the Adjustments and Repair procedures.

Repairs

Repairs include procedures for removal and replacement of parts which have the following special conditions:

When there is a personnel or machine safety issue.

When removal or replacement cannot be determined from the exploded view of the Parts List.

When there is a cleaning or a lubricating activity associated with the procedure. When the part requires an adjustment after replacement.

When a special tool is required for removal or replacement.

Use the repair procedures for the correct order of removal and replacement, for warnings, cautions, and notes.

Adjustments

Adjustments include procedures for adjusting the parts that must be within specification for the correct operation of the system.

Use the adjustment procedures for the correct sequence of operation for specifications, warnings, cautions and notes.

Section 5: Parts Lists

This section contains the Copier/Printer Parts List.

Section 6: General Procedures/Information

This section contains General Procedures, Diagnostic Programs, and Copier/Printer Information.

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

iii |

Section 7: Wiring Data

This section contains drawings, lists of plug/jack locations, and diagrams of the power distribution wire networks in the machine. This section also contains the Block Schematic Diagrams.

How to Use this Documentation

The Service Call Procedures in Section 1 describe the sequence of activities used during the service call. The call must be entered using these procedures.

Section 8: Options and Accessories

This section contains installation information for option and accessory.

Use of the Circuit Diagrams

All wirenets are shown on the Circuit Diagrams (CDs). Power distribution wirenets are shown in Section 7 (Wiring Data) of the Service Manual. The power distribution wirenets on the CDs will end at the terminal board for the power being distributed. Find the wirenet for that power and locate the terminal board on the wirenet. Use the wirenet to troubleshoot any power distribution wiring not shown on the CD.

Use of the Block Schematic Diagrams

Block Schematic Diagrams (BSDs) are included in Section 7 (Wiring Data) of the Service Manual. The BSDs show the functional relationship of the electrical circuitry to any mechanical, or non-mechanical, inputs or outputs throughout the machine. Inputs and outputs such as motor drive, mechanical linkages, operator actions, and air flow are shown. The BSDs will provide an overall view of how the entire subsystem works.

It should be noted that the BSDs no longer contain an Input Power Block referring to Chain 1. It will be necessary to refer to the Wirenets in order to trace a wire back to its source.

|

Introduction |

January 2007 |

Reversion 4.0 |

|

iv |

WorkCentre 7132 |

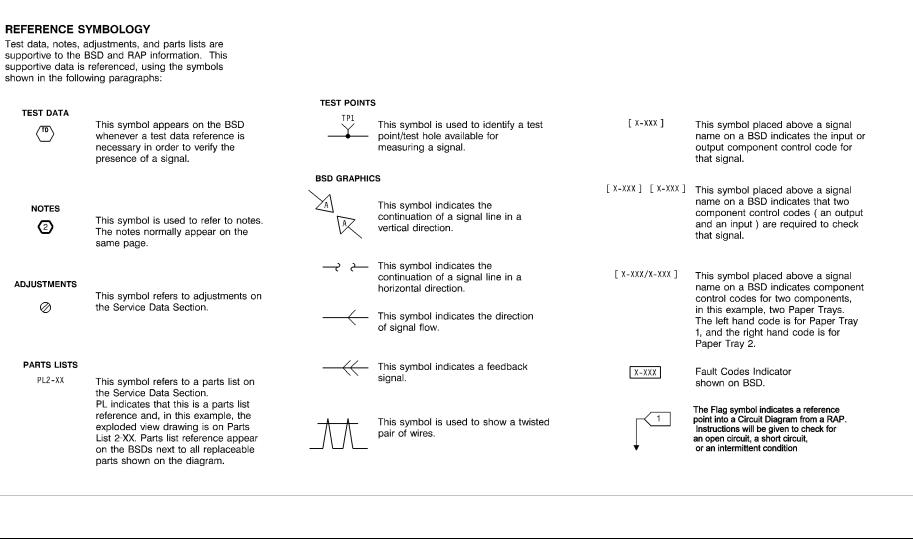

Symbology and Nomenclature

The following reference symbols are used throughout the documentation.

Warnings, Cautions, and Notes

Warnings, Cautions, and Notes will be found throughout the Service Documentation. The words WARNING or CAUTION may be listed on an illustration when the specific component associated with the potential hazard is pointed out; however, the message of the WARNING or CAUTION is always located in the text. Their definitions are as follows:

CAUTION

The use of controls or adjustments other than those specified in the Laser Safety Training Program may result in an exposure to dangerous laser radiation.

For additional information, review the Laser Safety Training program.

An arrow points to the location to install, to gain access to, or to release an object.

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, condition, or statement, if not strictly observed, could result in personal injury.

CAUTION

A Caution is used whenever an operating or maintenance procedure, a practice, condition, or statement, if not strictly observed, could result in damage to the equipment.

NOTE: A Note is used whenever it is necessary to highlight an operating or maintenance procedure, practice, condition, or statement.

Figure 2 Customer Access Label

This symbol indicates that a surface can be hot. Use caution when reaching in the machine to avoid touching the hot surfaces.

Machine Safety Icons

The following safety icons are displayed on the machine:

WARNING

This machine contains an invisible laser. There is no visual indication that the laser beam is present. During servicing, the machine is a Class 3B product because of the invisible laser. the laser beam could cause eye damage if looked at directly. Service procedures must be followed exactly as written without change. The service representative must observe the established local laser safety precautions when servicing the machine. Do not place tools with a reflective surface in the area of the ROS opening. Do not look in the area of the ROS window if the power is On and the laser is energized.

The following symbol and statement appear on a label in the machine. The symbol by itself, or the symbol and the statement may also appear in the service documentation and in the training program. When this symbol appears, the service representative is warned that conditions exist that could result in exposure to the laser beam.

WARNING

Do not try to bypass any laser interlocks for any reason. Permanent eye damage could result if the laser is accidentally directed into your eye.

Figure 1 Laser Hazard Symbol

Laser Hazard Statement

Figure 3 Heated Surface Label

Danger label indicates where electrical currents exist when the machine is closed and operating. Use caution when reaching in the machine.

Figure 4 Shock Hazard Label

These symbols indicate components that may be damaged by Electrostatic Discharge (ESD).

Figure 5 ESD warning Label

DANGER INVISIBLE LASER RADIATION WHEN OPEN. AVOID DIRECT EXPOSURE TO

BEAM.

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

v |

Electrostatic Discharge (ESD) Field Service Kit

The purpose of the ESD Protection Program is to preserve the inherent reliability and quality of electronic components that are handled by the Field Service Personnel. This program is being implemented now as a direct result of advances in microcircuitry technology, as well as a new acknowledgment of the magnitude of the ESD problem in the electronics industry today.

This program will reduce Field Service costs that are charged to PWB failures. Ninety percent of all PWB failures that are ESD related do not occur immediately. Using the ESD Field Service Kit will eliminate these delayed failures and intermittent problems caused by ESD. This will improve product reliability and reduce callbacks.

The ESD Field Service Kit should be used whenever Printed Wiring Boards or ESD sensitive components are being handled. This includes activities like replacing or reseating of circuit boards or connectors. The kit should also be used in order to prevent additional damage when circuit boards are returned for repair.

The instructions for using the ESD Field Service Kit can be found in ESD Field Service Kit Usage in the General Procedures section of the Service Documentation.

Illustration Symbols

Figure 6 shows symbols and conventions that are commonly used in illustrations.

Figure 6 Illustration Symbols

|

Introduction |

January 2007 |

Reversion 4.0 |

|

vi |

WorkCentre 7132 |

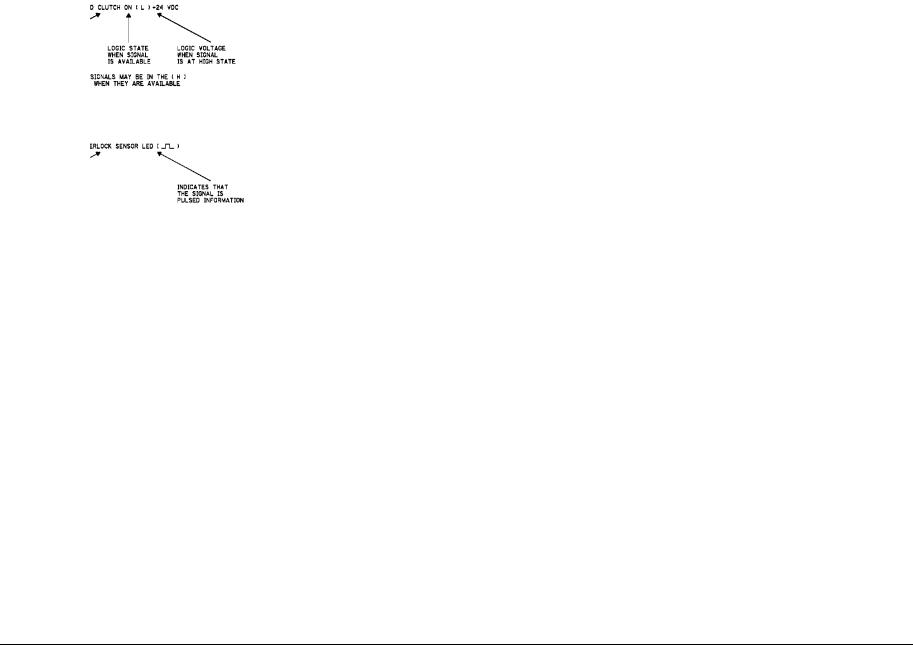

Signal Nomenclature

Refer to Figure 7 for an example of Signal Nomenclature used in Circuit Diagrams and BSDs.

Figure 7 Signal Nomenclature

DC Voltage Measurements in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC voltage, the first test point listed is the location for the red (+) meter lead and the second test point is the location for the black meter lead. For example, the following statement may be found in a RAP:

There is +5 VDC from TP7 to TP68.

In this example, the red meter lead would be placed on TP7 and the black meter lead on TP68.

Another example of a statement found in a RAP might be:

There is -15 VDC from TP21 to TP33.

In this example, the red meter lead would be placed on TP21 and the black meter lead would be placed on TP33.

If a second test point is not given, it is assumed that the black meter lead may be attached to the copier frame.

Voltage Measurement and Specifications

Measurements of DC voltage must be made with reference to the specified DC Common, unless some other point is referenced in a diagnostic procedure. All measurements of AC voltage should be made with respect to the adjacent return or ACN wire.

|

Table 1 Voltage Measurement and Specifications |

|

|

VOLTAGE |

SPECIFICATION |

|

INPUT POWER 220 V |

198 VAC TO 242 VAC |

|

INPUT POWER 100 V |

90 VAC TO 135 VAC |

|

INPUT POWER 120 V |

90 VAC TO 135 VAC |

|

+5 VDC |

+4.75 VDC TO +5.25 VDC |

|

+24 VDC |

+23.37 VDC TO +27.06 VDC |

Logic Voltage Levels

Measurements of logic levels must be made with reference to the specified DC Common, unless some other point is referenced in a diagnostic procedure.

|

Table 2 Logic Levels |

|

|

VOLTAGE |

H/L SPECIFICATIONS |

|

+5 VDC |

H= +3.00 TO +5.25 VDC |

|

L= 0.0 TO 0.8 VDC |

|

|

+24 VDC |

H= +23.37 TO +27.06 VDC |

|

L= 0.0 TO 0.8 VDC |

|

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

vii |

Introduction

Symbology and Nomenclature

WARNING

A Warning is used whenever an operating or maintenance procedure, a practice, condition, or statement, if not strictly observed, could result in personal injury.

DANGER: Une note DANGER est utilisée à chaque fois qu’une procédure de maintenance ou qu’une manipulation présente un risque de blessure si elle n’a pas été strictement observée.

WARNING

This machine contains an invisible laser. There is no visual indication that the laser beam is present. During servicing, the machine is a Class 3B product because of the invisible laser. the laser beam could cause eye damage if looked at directly. Service procedures must be followed exactly as written without change. The service representative must observe the established local laser safety precautions when servicing the machine. Do not place tools with a reflective surface in the area of the ROS opening. Do not look in the area of the ROS window if the power is On and the laser is energized.

DANGER: L’équipement contient un faisceau laser invisible et aucune indication visible signale la présence du faisceau laser. De ce fait le produit est classé 3B pour tout ce qui concerne la maintenance. L’exposition directe des yeux au faisceau laser peut entraîner des lésions visuelles. Les procédures de maintenance doivent être réalisées sans aucun changement comme indiqué dans la documentation. Le représentant Xerox lors d’interventions sur l’équipement doit respecter les consignes de sécurité locales concernant les faisceaux laser. Ne pas placer d’objet réfléchissant dans la zone du ROS quand il est ouvert. Ne pas regarder dans la zone du ROS lorsque la machine est sous tension et que le laser est en fonctionnement.

The following symbol and statement appear on a label in the machine. The symbol by itself, or the symbol and the statement may also appear in the service documentation and in the training program. When this symbol appears, the service representative is warned that conditions exist that could result in exposure to the laser beam.

DANGER: Les symboles et instructions suivants sont indiqués sur des étiquettes dans la machine et sont identifiés dans la documentation technique et dans le manuel de formation. Quand ces symboles s’affichent le représentant Xerox est prévenu des risques encourus concernant une exposition au rayon laser.

WARNING

nance ou reglage avec le cordon d’alimentation branche.

Paper Transportation

REP 2.1.1 Feeder 1 Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 2.3.1 Tray Feed/Nudger/Retard Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 2.4.1 Registration Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 2.5.1 Take Away Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 2.6.2 Left Hand (L/H) Upper Cover Unit

WARNING

Do not try to bypass any laser interlocks for any reason. Permanent eye damage could result if the laser is accidentally directed into your eye.

DANGER: Ne pas essayer de shunter les contacts laser pour quelques raisons que ce soit. Si le faisceau laser est dirigé accidentellement vers les yeux il peut en résulter des lésions oculaires permanentes.

4 Repairs and Adjustments

Drives

REP 1.1.1 Main Drive Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte-

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

ROS

REP 3.1.1 ROS Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Xerographics/Development

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

ix |

REP 4.1.1 Xero/Developer Cartridge

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 4.1.2 Toner Cartridge

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Electrical Components

REP 9.1.1 MCU PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 4.2.1 Dispense Motor

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 9.2.1 ESS PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Fuser

REP 5.1.1 Fuser Unit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Covers

REP 10.1.1 Top Cover Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Exit

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 10.2.1 Rear Lower Cover

REP 6.1.1 Exit 2 +OCT 2

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

MPT

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

IIT

REP 11.1.1 Platen Cushion

REP 7.1.1 MPT Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.1.2 Control Panel

|

REP 7.2.1 MPT Feed Roll/Retard Pad |

WARNING |

|

|

Introduction |

January 2007 |

Reversion 4.0 |

|

x |

WorkCentre 7132 |

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.3.1 Platen Glass

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.3.2 IIT/IPS PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.4.1 Lens Kit Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.5.1 Carriage Cable

REP 11.6.2 Lamp Wire Harness

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Tray Module -2T

REP 12.1.1 Tray 3 Feeder

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 12.1.2 Tray 3 Feeder (2TM)

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 12.3.1 Feed/Retard/Nudger Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.5.2 Carriage Motor

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 12.6.1 2 Tray Module PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 11.6.1 Exposure Lamp

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Tray Module -TT

REP 13.1.1 Tray 3 Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.1.2 Tray 2 Assembly (2TTM)

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

xi |

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.3.1 Front/Rear Tray Cable

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.4.1 Tray 3 Feeder (TTM)

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.5.1 Tray 3 Feeder

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.6.1 Feed/Retard/Nudger Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 13.8.1 Twin Tray Module PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

DADF

REP 15.1.1 DADF Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.1.2 DADF Platen Cushion

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.2.1 DADF Document Tray

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.2.2 DADF Feeder Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.2.3 DADF Front Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.2.4 DADF Rear Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.3.1 DADF PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.3.2 Left Counter Balance

|

Introduction |

January 2007 |

Reversion 4.0 |

|

xii |

WorkCentre 7132 |

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.3.3 Right Counter Balance

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.4.1 Retard Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.4.2 Top Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.6.1 Nudger Roll, Feed Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 15.8.1 Registration Roll

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

Finisher

REP 16.1.1 H-Transport Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.3.1 H-Transport Belt

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.1.2 Finisher Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.4.1 Front Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.4.2 Rear Cover

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.5.1 Stack Height Sensor Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.5.2 Eject Roll Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.6.1 Decurler Roll

|

Reversion 4.0 |

January 2007 |

Introduction |

|

WorkCentre 7132 |

xiii |

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.6.2 Finisher Drive Motor

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.7.1 Belt

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.8.1 Rail

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.8.2 Staple Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.9.1 Compiler Tray Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.10.1 Stacker Motor Assembly

nance ou reglage avec le cordon d’alimentation branche.

REP 16.10.2 Elevator Belt Assembly

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.11.1 Paddle Gear Shaft

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

REP 16.12.1 Finisher PWB

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

IIT

ADJ 11.6.1 Full/Half Rate carriage Position Adjustment

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer maintenance ou reglage avec le cordon d’alimentation branche.

8 Options and Accessories

8.1 FAX KIT

WARNING

Switch off the machine and disconnect the power cord.

DANGER: Mettre la machine sur ARRET et debrancher le cordon dalimentation.

8.2 Foreign Interface

WARNING

Switch off the machine and disconnect the power cord.

DANGER: Mettre la machine sur ARRET et debrancher le cordon dalimentation.

WARNING

To avoid personal injury or shock, do not perform repair or adjustment with electrical power applied to the machine.

DANGER: Afin d’eviter des blessures ou des chocs electriques, ne pas effectuer mainte-

|

Introduction |

January 2007 |

|

xiv |

Reversion 4.0

WorkCentre 7132

1 Service Call Procedures

|

Service Call Procedures…………………………………………………………………………………….. |

1-3 |

|

Initial Actions ……………………………………………………………………………………………………. |

1-3 |

|

Call Flow …………………………………………………………………………………………………………. |

1-4 |

|

Detailed Maintenance Activities (HFSI)………………………………………………………………… |

1-6 |

|

Cleaning Procedures…………………………………………………………………………………………. |

1-7 |

|

Final Actions…………………………………………………………………………………………………….. |

1-7 |

|

Reversion 4.0 |

January 2007 |

Service Call Procedures |

|

WorkCentre 7132 |

1-1 |

Service Call Procedures

Service Strategy

The service strategy for the WorkCentre 7132 is to perform any High Frequency Service Item (HFSI) actions before attempting to repair any problems. Some problems will be corrected by this strategy without the need to diagnose them. The Repair Analysis Procedures (RAPs) will be used for any remaining problems.

Problems that occur in the Basic Printer mode will be repaired before problems that occur when using the accessories.

Image Quality problems should be repaired after all other problems are repaired.

Service Call Procedures

The Service Call Procedures are a guide for performing any service on this machine. The procedures are designed to be used with the Service Manual. Perform each step in order.

Initial Actions

The Initial Actions gather information about the condition of the machine and the problem that caused the service call.

Call Flow

Call Flow summarizes the sequence of the Service Call Procedures.

Detailed Maintenance Activities

Detailed Maintenance Activities section provides the information needed to perform the High Frequency Service Item (HFSI) actions.

Cleaning Procedures

The Cleaning Procedures list what needs to be cleaned at each service call.

Final Actions

The Final Actions will test the copier/printer and return it to the customer. Administrative activities are also performed in the Final Actions.

Initial Actions

Purpose

The purpose of the Initial Action section of the Service Call Procedures is to determine the reason for the service call and to identify and organize the actions which must be performed.

Procedure

1.Gather the information about the service call and the condition of the copier/printer.

a.Question the operator(s). Ask about the location of most recent paper jams. Ask about the image quality and the copier/printer performance in general, including any unusual sounds or other indications.

b.After informing the customer, disconnect the machine from the customer’s network.

c.Check that the power cords are in good condition, correctly plugged in the power source, and free from any defects that would be a safety hazard. Repair or replace the power cords as required. Check that the circuit breakers are not tripped.

d.Inspect any rejected copies. Inquire as to, or otherwise determine, the paper quality and weight, the specified paper for optimum Image Quality, 24# Xerox Color Expressions (NASG) or ColorTech+90gsm (ESG). Look for any damage to the copies, oil marks, image quality defects, or other indications of a problem.

e.Record the billing meter readings.

f.Access Diagnostic Routines.

i.Enter UI Diagnostics (Entering UI Diagnostics in UI Diagnostic Mode).

ii.Access Diagnostic Routines (Accessing Diagnostic Routines in UI Diagnostic Mode).

NOTE: If a fault code is displayed while performing a diagnostics procedure, go to that fault code RAP and repair the fault. Return to Diagnostics and continue with the dC procedure that you were performing.

g.Print the HFSI Report and determine what HFSI action is required based on the customer output volume. Refer to the Detailed Maintenance Activities section for the detailed HFSI information. Record any items that require action.

h.Display and record the information in the Jam Counter, Fault Counter, and Shutdown History. Classify this information into categories:

Information that is related to the problem that caused the service call.

Information that is related to secondary problems.

Information that does not require action, such as a single occurrence of a problem.

i.Check the Service Log for any recent activities that are related to the problem that caused the service call or any secondary problem.

2.Perform any required HFSI activities identified above. Refer to the Detailed Maintenance Activities section.

3.Exit diagnostics. Try to duplicate the problem by running the same jobs that the customer was running.

4.Check the Image Quality in the Basic Copier Mode. Select the tray that is loaded with 11 x 17 or A3 paper, if unable to complete tray selection, go to Call Flow.

Set the copier/printer to the following setup:

• Output Color — Auto

|

Reversion 4.0 |

January 2007 |

Service Call Procedures |

|

Service Call Procedures, Initial Actions |

||

|

WorkCentre 7132 |

1-3 |

•Original Type — Photo and Text Halftone

•R/E — Auto

•Lighter/Darker — Auto Contrast

•Sharpness — Normal

•Preset Color Balance — Normal

•Color Shift — Normal

•Color Saturation — Normal

•Copy Position — No Shift

•Variable Color Balance — Normal

Run four copies of the Color Test Pattern.

Check the Image Quality. If the customer has identified any Image Quality Defects or problems, go to IQ1 IOT Image Quality Entry RAP.

5.Go to Call Flow.

Call Flow

This procedure should be performed at every service call.

Initial Actions

Ask the operator about the problem. If the problem appears to be related to operator error, or an attempt to perform a job outside of the machine specifications, assist the customer in learning the correct procedure.

Procedure

If the machine does not power up, Go to Power On RAP.

Ask the operator about the problem.

•If the problem is identified by a fault code (including Paper/Document Jams), refer to Chapter 2 for the procedure and then proceed with servicing.

•If the problem is noise or smell, select a mode (1 Sided/2Sided, Finisher etc.), find the cause of the problem and proceed with servicing.

The operator operated the machine correctly.

YN

Explain to the operator how to operate the machine correctly.

The UI display is normal.

Y N

|

Go to OF 6 Dark/Blank Display. Refer to BSDs (CH2.1-CH2.4). |

|||||||||

|

The problem occurs only in Print mode. |

|||||||||

|

Y |

N |

||||||||

|

The problem occurs only in Copy mode. |

|||||||||

|

Y |

N |

||||||||

|

The problem occurs only in Fax mode. |

|||||||||

|

Y |

N |

||||||||

|

The problem is an accessory or the Foreign Accessory. |

|||||||||

|

Y |

N |

||||||||

|

Refer to Table 1 Other Faults and identify the problem and follow the cor- |

|||||||||

|

rective action. |

|||||||||

|

If the cause of the problem is an accessory or the Foreign Interface, check that |

|||||||||

|

the machine settings are correct, refer to the appropriate service manual for the |

|||||||||

|

procedure and then proceed with servicing. |

|||||||||

|

The problem occurs only in certain modes such as Broadcast transmission. |

|||||||||

|

Y |

N |

||||||||

|

Perform a transmission test with the call center or station. The problem reoc- |

|||||||||

|

curs. |

|||||||||

|

Y |

N |

||||||||

|

Ask the customer for permission to establish communications with |

|||||||||

|

the remote machine that is causing the problem. Perform a Send |

|||||||||

|

transmission test with the remote machine. Transmission was nor- |

|||||||||

|

mal. |

|||||||||

|

A |

B |

C |

D |

||||||

|

Service Call Procedures |

January 2007 |

Reversion 4.0 |

|||||||

|

Initial Actions, Call Flow |

|||||||||

|

1-4 |

WorkCentre 7132 |

A B C D

YN

Print the protocol trace to identify whether it is the remote machine or the machine that is causing the problem.

•If the problem lies in the machine:

Analyze the protocol trace, refer to Chapter 2 and then proceed with servicing.

•If the problem appears to lie in the remote machine:

Ask the customer to check the status of the remote machine.

There is a problem with Receive transmission test. Perform Receive transmission tests with other stations within the company. Check that there is no problem with the machine and then ask the customer to check the status of the remote machine.

Analyze the protocol trace, refer to Chapter 2 and then proceed with servicing.

Check the machine settings and if necessary, ask the customer for permission to test the machine in the mode in which the problem occurs.

Analyze the protocol trace when the problem reoccurs, refer to Chapter 2 and then proceed with servicing.

There is an image quality problem.

YN

If there is an alignment problem, obtain separate Platen/DADF output samples, refer to Chapter 4 Adjustments and then proceed with servicing.

Refer to Chapter 3 IQ1 IOT Image Quality Entry RAP and then proceed with servicing.

There is a problem with the network.

YN

There is a problem with the USB connection. Y N

There is an image quality problem. Y N

The problem lies in a certain Client PC. Y N

There is a problem with a certain application or programming language A. Obtain the latest information on restrictions and technical information. Proceed accordingly.

Check the settings of that particular Client PC and if necessary ask the user to reinstall the printer driver.

Refer to IQ1 IOT Image Quality Entry RAP and then proceed with servicing. If the problem persists, ask the user to reinstall the printer driver.

Check the machine settings and if necessary ask the user to reinstall the printer driver.

E

If the problem continues, replace the network cable. If the problem persists, replace the USB cable. Check the machine settings and discuss the problem with the customer’s network administrator.

|

Table 1 Other Faults |

|

|

Problem |

Corrective Action |

|

Duplexing is not available as a |

Ensure the Duplex electrical connector is secure (PL |

|

selection on the display. |

10.1) |

|

Copies jam in the Finisher when |

Verify condition of paper. If good, check that part |

|

the output tray is near maximum |

655N128 can be used to support tray. |

|

capacity. |

|

|

ADF inoperative after PWB |

Reload Software ADJ 9.3.1. |

|

replacement. |

|

|

Can not make copies when |

Enter UI Diagnostic Mode. Select Copy on screen. |

|

Auditron is enabled. |

Machine will operate without auditron restriction. |

|

Loud snapping noise is heard. |

Enter Component Control [042-003] and press the Start |

|

button. If noise is present there is binding in toner auger |

|

|

drive system. Repair as required (PL 1.2) |

|

|

Sets are not offset in Center Tray. |

Perform Center Tray Offsetting. |

|

E-mail icon not visible in display on |

Perform E-Mail Icon. |

|

email enabled machine. |

|

|

Customer wishes to distinguish |

Perform FAX Output Separation. |

|

FAX output from prints or copies. |

|

E

|

Reversion 4.0 |

January 2007 |

Service Call Procedures |

|

Call Flow |

||

|

WorkCentre 7132 |

1-5 |

Detailed Maintenance Activities (HFSI)

Procedure

1.Access Diagnostic Routines.

a.Enter UI Diagnostics (Entering UI Diagnostics in UI Diagnostic Mode).

b.Access Diagnostic Routines (Accessing Diagnostic Routines in UI Diagnostic Mode).

2.Select NVM Read/Write.

3.Refer to Table 1 and enter a counter number for any High Frequency Service Item (HFSI) counters to be checked. Use the customer’s output volume numbers to help determine which HFSI components should be serviced. Consider components near threshold as candidates for service.

4.Refer to Cleaning Procedures for detailed cleaning instructions.

Table 1 High Frequency Service Items

|

Counter |

Name |

Threshold |

Service Action to be performed |

|

954-800 |

Tray 1 Feed counter |

300K |

Replace the Feed Roll, Retard Roll, Nudger |

|

Roll. |

|||

|

954-801 |

Tray 2 Feed counter |

300K |

Replace the Feed Roll, Retard Roll, Nudger |

|

Roll. |

|||

|

954-802 |

Tray 3 Feed counter |

300K |

Replace the Feed Roll, Retard Roll, Nudger |

|

Roll. |

|||

|

954-803 |

MSI Feed counter |

50K |

Replace the Feed Roll, Retard Pad. |

|

954-824 |

IBT Belt counter |

480K |

Replace the IBT Assembly. |

|

954-825 |

IBT Cleaner counter |

100K |

Replace the IBT Cleaner. |

|

954-826 |

2nd BTR Counter |

300K |

Replace the Bias Transfer Roll. |

|

954-830 |

K Developer Counter |

420K |

Replace the K Developer. |

|

954-831 |

Y Developer Counter |

420K |

Replace the Y Developer. |

|

954-832 |

M Developer Counter |

420K |

Replace the M Developer. |

|

954-833 |

C Developer Counter |

420K |

Replace the C Developer. |

|

954-837 |

Xero Drum Counter |

10M |

Replace the Xero Drum Assembly. |

|

954-842 |

Fuser Counter |

10M |

Replace the Fuser Assembly. |

|

956-802 |

Lamp Scan Counter |

6000K |

Replace the Exposure Lamp. |

|

956-803 |

Exposure Lamp Time |

7200K |

Replace the Exposure Lamp. |

|

Counter |

|||

|

956-804 |

Exposure Lamp On |

6000K |

Replace the Exposure Lamp. |

|

Counter |

|||

|

955-806 |

CVT Feed Counter |

200K |

Replace the Document Nudger Roll, Feed |

|

Roll, Retard Roll, Registration Roll. |

|||

|

955-807 |

Simplex Feed Counter |

912K |

Replace the Document Nudger Roll, Feed |

|

Roll, Retard Roll, Registration Roll. |

|||

|

955-808 |

Duplex Feed Counter |

912K |

Replace the Document Nudger Roll, Feed |

|